Description

Product details

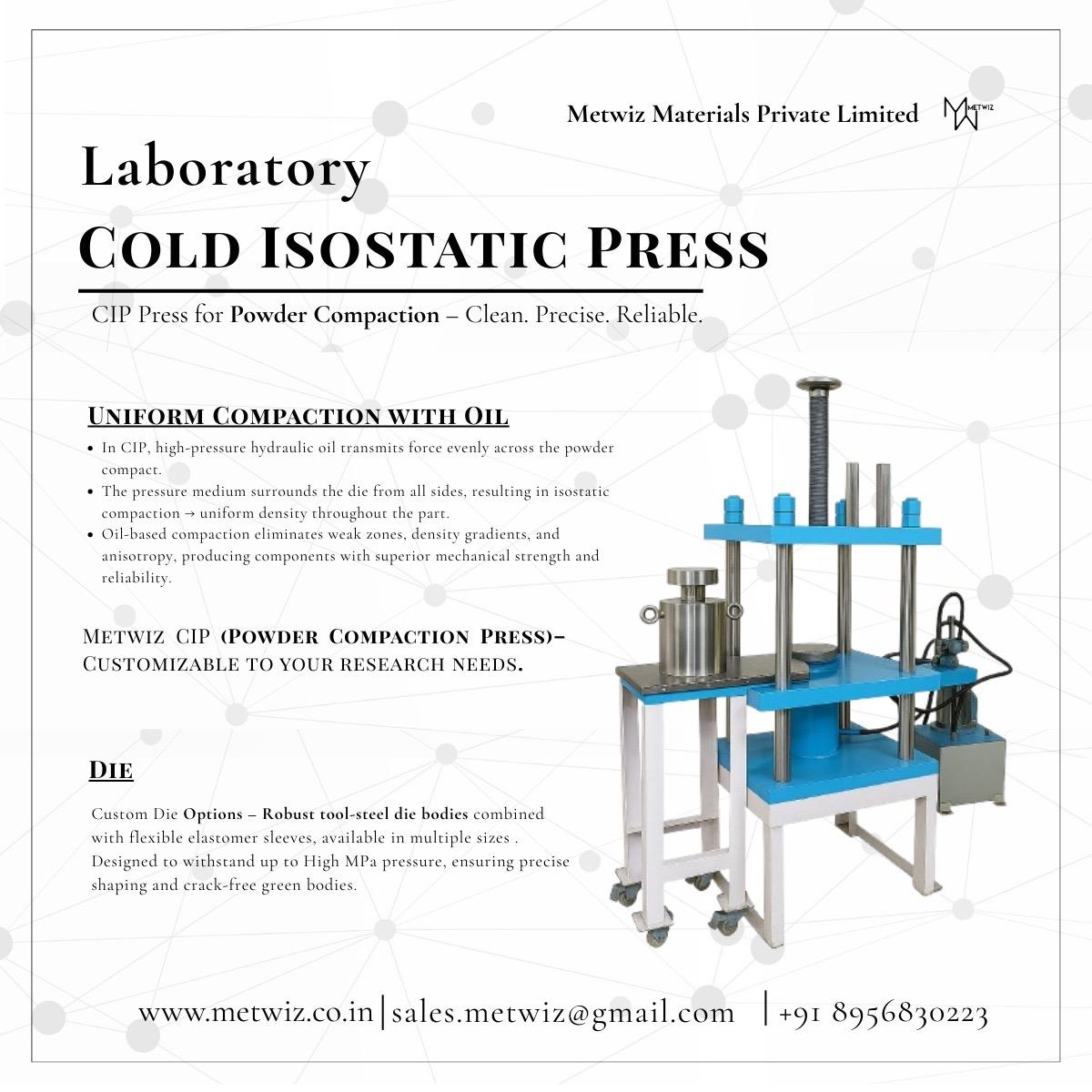

This advanced laboratory equipment is designed for powder compaction using cold isostatic pressing—a method that applies uniform hydraulic pressure to shape powders into dense, crack-free green bodies. It’s ideal for research labs, material testing, and precision manufacturing. ⚙️ Key Features & Components - Uniform Compaction with Oil: - Uses high-pressure hydraulic oil to transmit force evenly across the powder compact. - The pressure medium surrounds the die from all sides, ensuring isostatic compaction. - Eliminates air voids, increases green strength, and improves dimensional accuracy. - Robust Construction: - Mounted on a blue steel frame with wheels for easy mobility. - Includes a stainless steel pressure vessel, hydraulic cylinders, and a control panel. - Customizable Design: - Offers custom die options made from tool steel. - Flexible die-release systems available in multiple sizes. - Rated for pressures up to 300 MPa, ensuring precise shaping and high mechanical strength. - Control Panel: - Allows for precise adjustment of pressure settings and operation timing. - Designed for clean, reliable, and repeatable performance. 🧩 Applications - Powder metallurgy - Ceramic and composite material research - Advanced material prototyping - Green body formation for sintering